THREADED FLANGES

Threaded Flanges are confined to special applications. Their chief merit lies in the fact that they can be assembled without welding this explains their use in extremely high pressure services, particularly at or near atmospheric temperature, when alloy steel is essential for strength and where the necessary post weld heat treatment is impractical. Threaded Flanges are unsuited for conditions involving temperature or bending stresses of any magnitude, particularly under cyclic conditions, where leakage through the threads may occur in relatively few cycles of heating or stress; sea welding is sometimes employed to overcome this, but cannot be considered as entirely satisfaction.

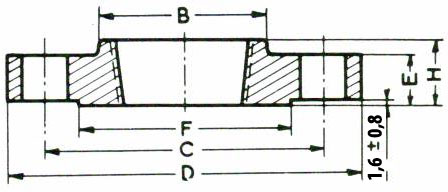

Dimensions

Diameter : 1/2" à 24"

Pressure class : 150# - 300# - 600# - 1500#

Variations

- Face finish : Raised face (RF) - Flat face (FF) - RTJ

- Variations : Reducing Threaded

Standards

- ASTM A182 - ASME SA182 - 'Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings'

- ASME B16.5 - 'Pipe Flanges and Flanged Fittings'

- MSS SP-6 - 'Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings'

150 Lbs

| Drilling | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 90 | 9.6 | 35.05 | 30 | 14 | 4 | 15.87 | 60.3 |

| 3/4" | 100 | 11.2 | 42.92 | 38 | 14 | 4 | 15.87 | 69.9 |

| 1" | 110 | 12.7 | 50.80 | 49 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4" | 115 | 14.3 | 63.50 | 59 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2" | 125 | 15.9 | 73.15 | 65 | 21 | 4 | 15.87 | 98.4 |

| 2" | 150 | 17.5 | 91.94 | 78 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2" | 180 | 20.7 | 104.65 | 90 | 27 | 4 | 19.05 | 139.7 |

| 3" | 190 | 22.3 | 127.00 | 108 | 29 | 4 | 19.05 | 152.4 |

| 3 1/2" | 215 | 22.3 | 139.70 | 122 | 30 | 8 | 19.05 | 177.8 |

| 4" | 230 | 22.3 | 157.22 | 135 | 32 | 8 | 19.05 | 190.5 |

| 5" | 255 | 22.3 | 185.67 | 164 | 35 | 8 | 22.22 | 215.9 |

| 6" | 280 | 23.9 | 215.90 | 192 | 38 | 8 | 22.22 | 241.3 |

| 8" | 345 | 27.0 | 269.75 | 246 | 43 | 8 | 22.22 | 298.5 |

| 10" | 405 | 28.6 | 323.85 | 305 | 48 | 12 | 25.40 | 362.0 |

| 12" | 485 | 30.2 | 381.00 | 365 | 54 | 12 | 25.40 | 431.8 |

| 14" | 535 | 33.4 | 412.75 | 400 | 56 | 12 | 28.57 | 476.3 |

| 16" | 595 | 35.0 | 469.90 | 457 | 62 | 16 | 28.57 | 539.8 |

| 18" | 635 | 38.1 | 533.40 | 505 | 67 | 16 | 31.75 | 577.9 |

| 20" | 700 | 41.3 | 584.20 | 559 | 71 | 20 | 31.75 | 635.0 |

| 24" | 815 | 46.1 | 692.15 | 663 | 81 | 20 | 34.92 | 749.3 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 - 2007

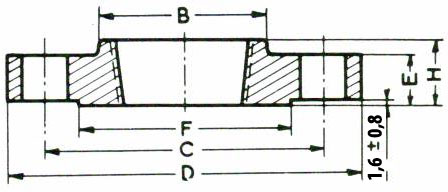

300 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 95 | 12.7 | 35.05 | 38 | 23.6 | 21 | 4 | 15.87 | 66.7 |

| 3/4" | 115 | 14.3 | 42.92 | 48 | 29.0 | 24 | 4 | 19.05 | 82.6 |

| 1" | 125 | 15.9 | 50.80 | 54 | 35.8 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4" | 135 | 17.5 | 63.50 | 64 | 44.4 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2" | 155 | 19.1 | 73.15 | 70 | 50.3 | 29 | 8 | 22.22 | 114.3 |

| 2" | 165 | 20.7 | 91.94 | 84 | 63.5 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2" | 190 | 23.9 | 104.65 | 100 | 76.2 | 37 | 8 | 22.22 | 149.2 |

| 3" | 210 | 27.0 | 127.00 | 117 | 92.2 | 41 | 8 | 22.22 | 168.3 |

| 3 1/2" | 230 | 28.6 | 139.70 | 133 | 104.9 | 43 | 8 | 22.22 | 184.2 |

| 4" | 255 | 30.2 | 157.22 | 146 | 117.6 | 46 | 8 | 22.22 | 200.0 |

| 5" | 280 | 33.4 | 185.67 | 178 | 144.4 | 49 | 8 | 22.22 | 235.0 |

| 6" | 320 | 35.0 | 215.90 | 206 | 171.4 | 51 | 12 | 22.22 | 269.9 |

| 8" | 380 | 39.7 | 269.75 | 260 | 222.2 | 60 | 12 | 25.40 | 330.2 |

| 10" | 445 | 46.1 | 323.85 | 321 | 276.2 | 65 | 16 | 28.57 | 387.4 |

| 12" | 520 | 49.3 | 381.00 | 375 | 328.6 | 71 | 16 | 31.75 | 450.8 |

| 14" | 585 | 52.4 | 412.75 | 425 | 360.4 | 75 | 20 | 31.75 | 514.4 |

| 16" | 650 | 55.6 | 469.90 | 483 | 411.2 | 81 | 20 | 34.92 | 571.5 |

| 18" | 710 | 58.8 | 533.40 | 533 | 462.0 | 87 | 24 | 34.92 | 628.6 |

| 20" | 775 | 62.0 | 584.20 | 587 | 512.8 | 94 | 24 | 34.92 | 685.8 |

| 24" | 915 | 68.3 | 692.15 | 702 | 614.4 | 105 | 24 | 41.27 | 812.8 |

1,6mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 - 2007

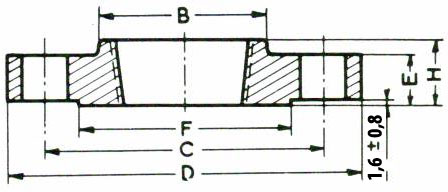

600 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 95 | 14.3 | 35.05 | 38 | 23.6 | 22 | 4 | 15.87 | 66.7 |

| 3/4" | 115 | 15.9 | 42.92 | 48 | 29.0 | 25 | 4 | 19.05 | 82.6 |

| 1" | 125 | 17.5 | 50.80 | 54 | 35.8 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4" | 135 | 20.7 | 63.50 | 64 | 44.4 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2" | 155 | 22.3 | 73.15 | 70 | 50.6 | 32 | 4 | 22.22 | 114.3 |

| 2" | 165 | 25.4 | 91.94 | 84 | 63.5 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2" | 190 | 28.6 | 104.65 | 100 | 76.2 | 41 | 8 | 22.22 | 149.2 |

| 3" | 210 | 31.8 | 127.00 | 117 | 92.2 | 46 | 8 | 22.22 | 168.3 |

| 3 1/2" | 230 | 35.0 | 139.70 | 133 | 104.9 | 49 | 8 | 25.40 | 184.2 |

| 4" | 275 | 38.1 | 157.22 | 152 | 117.6 | 54 | 8 | 25.40 | 215.9 |

| 5" | 330 | 44.5 | 185.67 | 189 | 144.4 | 60 | 8 | 28.57 | 266.7 |

| 6" | 355 | 47.7 | 215.90 | 222 | 171.4 | 67 | 12 | 31.75 | 292.1 |

| 8" | 420 | 55.6 | 269.75 | 273 | 222.2 | 76 | 12 | 31.75 | 349.2 |

| 10" | 510 | 63.5 | 323.85 | 343 | 276.2 | 86 | 16 | 34.92 | 431.8 |

| 12" | 560 | 66.7 | 381.00 | 400 | 328.6 | 92 | 20 | 34.92 | 489.0 |

| 14" | 605 | 69.9 | 412.75 | 432 | 360.4 | 94 | 20 | 38.10 | 527.0 |

| 16" | 685 | 76.2 | 469.90 | 495 | 411.2 | 106 | 20 | 41.27 | 603.2 |

| 18" | 745 | 82.6 | 533.40 | 546 | 462.0 | 117 | 20 | 44.45 | 654.0 |

| 20" | 815 | 88.9 | 584.20 | 610 | 512.8 | 127 | 24 | 44.45 | 723.9 |

| 24" | 940 | 101.6 | 692.15 | 718 | 614.4 | 140 | 24 | 47.62 | 838.2 |

6,4mm raised face not included in the E & H dimensions

The dimensions are in millimeters

Source : ASME B16.5 - 2007