SOCKET WELD FLANGES

Socket welding flange, a popular type of pipe flange, was initially developed for use on small-sized high- pressure piping. The fabrication of this type of flange is similar to that of a slip-on flange. However, the internal pocket of a socket weld flange allows for a smooth bore and better fluid flow. When provided with an internal weld, the static strength of this flange is equal to slip-on flange, but the fatigue strength is 50% greater than double welding slip-on flanges. Smooth bore conditions in such a flange can easily be attained without having to bevel the flange face and, after welding, to re-face the socket weld flange as would be required with slip-on flanges. For this reason, the internally welded flange is popular in chemical process piping. The counter bore is sightly larger than the Outer Diameter of the matching pipe, allowing the pipe to be inserted. A restriction is built into the bottom of the bore, which acts as a shoulder for the pipe to rest on, and has the same I.D. of matching pipe. The flow is not restricted in any direction.

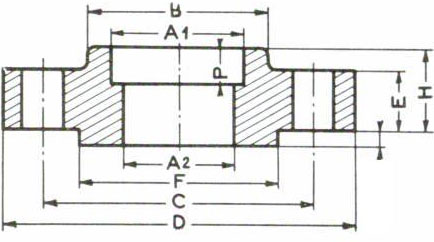

Dimensions

Diameter : 1/2" à 24"

pressure class : 150# - 300# - 600# - 1500#

Schedules : SCH10S - SCH40S - SCH80S - SCH160

Variations

- Face finish : Raised face (RF) - Flat face (FF) - RTJ -

- Variations : Reducing Socket Weld

Standards

ASTM A182 - ASME SA182 - 'Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings'

ASME B16.5 - 'Pipe Flanges and Flanged Fittings'

MSS SP-6 - 'Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves and Fittings'

150 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 90 | 11.2 | 35.05 | 30 | 22.2 | 14 | 4 | 15.87 | 60.3 |

| 3/4" | 100 | 12.7 | 42.92 | 38 | 27.7 | 14 | 4 | 15.87 | 69.9 |

| 1" | 110 | 14.3 | 50.80 | 49 | 34.5 | 16 | 4 | 15.87 | 79.4 |

| 1 1/4" | 115 | 15.9 | 63.50 | 59 | 43.2 | 19 | 4 | 15.87 | 88.9 |

| 1 1/2" | 125 | 17.5 | 73.15 | 65 | 49.5 | 21 | 4 | 15.87 | 98.4 |

| 2" | 150 | 19.1 | 91.94 | 78 | 61.9 | 24 | 4 | 19.05 | 120.7 |

| 2 1/2" | 180 | 22.3 | 104.65 | 90 | 74.6 | 27 | 4 | 19.05 | 139.7 |

| 3" | 190 | 23.9 | 127.00 | 108 | 90.7 | 29 | 4 | 19.05 | 152.4 |

1,6mm raised face not included in the E & H dimensions

See below for the A2 dimension

The dimensions are in millimeters

Source : ASME B16.5 - 2007

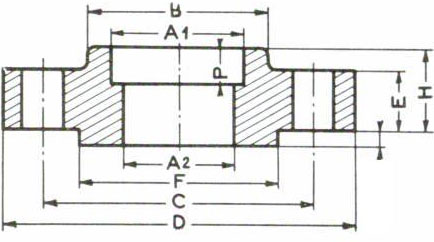

300 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 95 | 12.7 | 35.05 | 38 | 22.2 | 21 | 4 | 15.87 | 66.7 |

| 3/4" | 115 | 14.3 | 42.92 | 48 | 27.7 | 24 | 4 | 19.05 | 82.6 |

| 1" | 125 | 15.9 | 50.80 | 54 | 34.5 | 25 | 4 | 19.05 | 88.9 |

| 1 1/4" | 135 | 17.5 | 63.50 | 64 | 43.2 | 25 | 4 | 19.05 | 98.4 |

| 1 1/2" | 155 | 19.1 | 73.15 | 70 | 49.5 | 29 | 4 | 22.22 | 114.3 |

| 2" | 165 | 20.7 | 91.94 | 84 | 61.9 | 32 | 8 | 19.05 | 127.0 |

| 2 1/2" | 190 | 23.9 | 104.65 | 100 | 74.6 | 37 | 8 | 22.22 | 149.2 |

| 3" | 210 | 27.0 | 127.00 | 117 | 90.7 | 41 | 8 | 22.22 | 168.3 |

1,6mm raised face not included in the E & H dimensions

See below for the A2 dimension

The dimensions are in millimeters

Source : ASME B16.5 - 2007

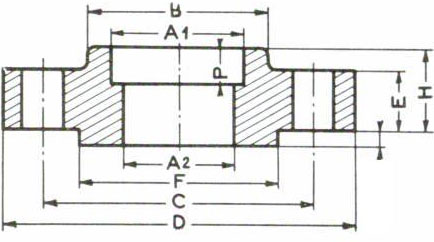

600 Lbs

| Drilling | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal Bore | >Dia. (D) |

Thick. (E) |

Dia. (F) |

Dia. (B) |

Dia. (A) |

Height1 (H) |

Nbr | Holes | Dia. (C) |

| 1/2" | 95 | 14.3 | 35.05 | 38 | 22.2 | 22 | 4 | 15.87 | 66.7 |

| 3/4" | 115 | 15.9 | 42.92 | 48 | 27.7 | 25 | 4 | 19.05 | 82.6 |

| 1" | 125 | 17.5 | 50.80 | 54 | 34.5 | 27 | 4 | 19.05 | 88.9 |

| 1 1/4" | 135 | 20.7 | 63.50 | 64 | 43.2 | 29 | 4 | 19.05 | 98.4 |

| 1 1/2" | 155 | 22.3 | 73.15 | 70 | 49.5 | 32 | 4 | 22.22 | 114.3 |

| 2" | 165 | 25.4 | 91.94 | 84 | 61.9 | 37 | 8 | 19.05 | 127.0 |

| 2 1/2" | 190 | 28.6 | 104.65 | 100 | 74.6 | 41 | 8 | 22.22 | 149.2 |

| 3" | 210 | 31.8 | 127.00 | 117 | 90.7 | 46 | 8 | 22.22 | 168.3 |

6,4mm raised face not included in the E & H dimensions

See below for the A2 dimension

The dimensions are in millimeters

Source : ASME B16.5 - 2007

InNER diameter depending on thicknesses - A2

| Nominal Bore | SCH10S | SCH40S | SCH80S | SCH160 |

|---|---|---|---|---|

| 1/2" | 17.1 | 15.8 | 13.9 | 11.8 |

| 3/4" | 22.4 | 20.9 | 18.8 | 15.6 |

| 1" | 27.8 | 26.6 | 24.3 | 20.7 |

| 1 1/4" | 36.6 | 35.1 | 32.5 | 29.5 |

| 1 1/2" | 42.7 | 40.9 | 38.1 | 34 |

| 2" | 54.7 | 52.5 | 49.2 | 42.9 |

| 2 1/2" | 66.9 | 62.7 | 59 | 54 |

| 3" | 82.8 | 77.9 | 73.7 | 66.7 |

The dimensions are in millimeters

Source : ASME B16.5 - 2007