BUTTWELD FITTINGS

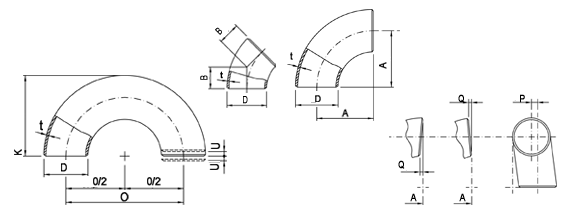

45° SHORT RADIUS ELBOW

We are globally well renowned as the Best Quality Buttweld Fittings manufacturer in India. We cater an ample assortment of Buttweld Fittings which is incorporated using high technology machines. Our Buttweld Fittings are demanded by all due to their less maintenance, high tensile strength and excellent finish. High reliability and durability are the salient features of our Buttweld Fittings. We stand in the midst of predominant Buttweld Fittings suppliers in India. We deliver our Buttweld Fittings at very competitive prices and within the specified time.

| Standards: | ANSI - B 16.9 ASTM A403 - ASME SA403 - 'Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings' API 590-605 ASME B16.9 - 'Factory-Made Wrought Buttwelding Fittings'' ASME B16.25 - 'Buttwelding Ends' ASME B16.28 - 'Wrought Steel Buttwelding Short Radius Elbows and Returns' MSS SP-43 - 'Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications' |

| Schedule: | Sch 5 TO Sch XXS. |

| Sizes: | Diameters - from 21,3 to 711 mm. Wall Thickness - from 2 to 40 mm. |

| Materials: | Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30 Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: | Butt Weld (BW) |

| Thickness: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

Dimensions

Nom.

Pipe

Size |

Pipe

Sched.

or No. |

Center-

to-end

Dimen. |

Outside

Dia. |

Inside

Dia. |

Wall

Thick. |

Approx.

Weight

(lb.) |

| F | OD | ID | T | |||

| STANDARD WEIGHT | ||||||

| 1/2 | 40 | 5/8 | 0.840 | 0.622 | 0.109 | 0.1 |

| 3/4 | 40 | 7/16 | 1.050 | 0.824 | 0.113 | 0.1 |

| 1 | 40 | 7/8 | 1.315 | 1.049 | 0.133 | 0.2 |

| 1 1/4 | 40 | 1 | 1.660 | 1.380 | 0.140 | 0.4 |

| 1 1/2 | 40 | 1 1/8 | 1.900 | 1.610 | 0.145 | 0.5 |

| 2 | 40 | 1 3/8 | 2.375 | 2.067 | 0.154 | 0.9 |

| 2 1/2 | 40 | 1 3/4 | 2.875 | 2.469 | 0.203 | 1.5 |

| 3 | 40 | 2 | 3.500 | 3.068 | 0.216 | 2.5 |

| 3 1/2 | 40 | 2 1/4 | 4.000 | 3.548 | 0.226 | 3.5 |

| 4 | 40 | 2 1/2 | 4.500 | 4.026 | 0.237 | 4.8 |

| 5 | 40 | 3 1/8 | 5.563 | 5.047 | 0.258 | 7.8 |

| 6 | 40 | 3 3/4 | 6.625 | 6.065 | 0.280 | 12 |

| 8 | 40 | 5 | 8.625 | 7.981 | 0.322 | 23 |

| 10 | 40 | 6 1/4 | 10.750 | 10.020 | 0.365 | 42 |

| 12 | - | 7 1/2 | 12.750 | 12.000 | 0.375 | 61 |

| 14 | 30 | 8 3/4 | 14.000 | 13.250 | 0.375 | 79 |

| 16 | 30 | 10 | 16.000 | 15.250 | 0.375 | 103 |

| 18 | - | 11 1/4 | 18.000 | 17.250 | 0.375 | 132 |

| 20 | 20 | 12 1/2 | 20.000 | 19.250 | 0.375 | 160 |

| 22 | 20 | 13 1/2 | 22.000 | 21.250 | 0.375 | 195 |

| 24 | 20 | 15 | 24.000 | 23.250 | 0.375 | 238 |

| EXTRA STRONG | ||||||

Nom.

Pipe

Size |

Pipe

Sched.

or No. |

Center-

to-end

Dimen. |

Outside

Dia. |

Inside

Dia. |

Wall

Thick. |

Approx.

Weight

(lb.) |

| F | OD | ID | T | |||

| 1/2 | 80 | 5/8 | 0.840 | 0.546 | 0.147 | 0.2 |

| 3/4 | 80 | 7/16 | 1.050 | 0.742 | 0.154 | 0.3 |

| 1 | 80 | 7/8 | 1.315 | 0.957 | 0.179 | 0.4 |

| 1 1/4 | 80 | 1 | 1.660 | 1.278 | 0.191 | 0.5 |

| 1 1/2 | 80 | 1 1/8 | 1.900 | 1.500 | 0.200 | 0.6 |

| 2 | 80 | 1 3/8 | 2.375 | 1.939 | 0.218 | 1.1 |

| 2 1/2 | 80 | 1 3/4 | 2.875 | 2.323 | 0.276 | 2.1 |

| 3 | 80 | 2 | 3.500 | 2.900 | 0.300 | 3.5 |

| 3 1/2 | 80 | 2 1/4 | 4.000 | 3.364 | 0.318 | 4.8 |

| 4 | 80 | 2 1/2 | 4.500 | 3.826 | 0.337 | 6.5 |

| 5 | 80 | 3 1/8 | 5.563 | 4.813 | 0.375 | 11 |

| 6 | 80 | 3 3/4 | 6.625 | 5.761 | 0.432 | 18 |

| 8 | 80 | 5 | 8.625 | 7.625 | 0.500 | 35 |

| 10 | 60 | 6 1/4 | 10.750 | 9.750 | 0.500 | 56 |

| 12 | - | 7 1/2 | 12.750 | 11.750 | 0.500 | 80 |

| 14 | - | 8 3/4 | 14.000 | 13.000 | 0.500 | 100 |

| 16 | 40 | 10 | 16.000 | 15.000 | 0.500 | 131 |

| 18 | - | 11 1/4 | 18.000 | 17.000 | 0.500 | 172 |

| 20 | 30 | 12 1/2 | 20.000 | 19.000 | 0.500 | 210 |

| 22 | 30 | 13 1/2 | 22.000 | 21.000 | 0.500 | 259 |

| 24 | - | 15 | 24.000 | 23.000 | 0.500 | 302 |

ELBOWS - Ansi 16.9 tolerances

| DIMENSIONAL TOLERANCES - ELBOWS | |||||||

| For all fittings | Elbows 90/45 deg | 180° Returns | |||||

| Nominal Pipe Size (NPS) | Outside Ø at Bevel |

Inside Ø at End |

Wall Thickness t / t1 |

Center to End Dim. A-B-C-M | Center to Center Dim. O |

Back to Face Dim. K |

Align- ment of Ends U |

| 1/2 a 2 1/2 | 1 | 0,8 | Not | 2 | 7 | 7 | 1 |

| 3 a 3 1/2 | 1 | 1,6 | less | 2 | 7 | 7 | 1 |

| 4 | +2 -1 | 1,6 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | +3 -1 | 1,6 | 87,50% | 2 | 7 | 7 | 1 |

| 8 | 2 | 1,6 | of nominal | 2 | 7 | 7 | 1 |

| 10 | +4 -3 | 3,2 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | +4 -3 | 3,2 | 3 | 10 | 7 | 2 | |

| 20 a 24 | +6 -5 | 4,8 | 3 | 10 | 7 | 2 | |

| 26 a 30 | +7 -5 | 4,8 | 3 | ..... | ..... | ..... | |

| 32 a 48 | +7 -5 | 4,8 | 5 | ..... | ..... | ..... | |

| Angularity Tolerances | ||

| ND | Max off angle | Max off plane |

| Q | P | |

| 1/2 a 4 | 1 | 2 |

| 5 a 8 | 2 | 4 |

| 10 a 12 | 3 | 5 |

| 14 a 16 | 3 | 7 |

| 18 a 24 | 4 | 10 |

| 26 a 30 | 5 | 10 |

| 32 a 42 | 5 | 13 |

| 44 a 48 | 5 | 20 |

ELBOWS - Weights

| WEIGHTS OF FITTINGS | ||||||||

| NPS inches |

ELBOWS LR 90° |

ELBOWS SR 90° |

||||||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.05 | 0.06 | 0.08 | 0.10 | 0.03 | 0.04 | 0.05 | 0.07 |

| 3/4 | 0.06 | 0.07 | 0.09 | 0.11 | 0.04 | 0.05 | 0.06 | 0.07 |

| 1 | 0.09 | 0.15 | 0.18 | 0.20 | 0.06 | 0.10 | 0.12 | 0.13 |

| 1 1/4 | 0.13 | 0.20 | 0.25 | 0.35 | 0.09 | 0.13 | 0.17 | 0.12 |

| 1 1/2 | 0.18 | 0.30 | 0.40 | 0.50 | 0.12 | 0.20 | 0.27 | 0.33 |

| 2 | 0.30 | 0.50 | 0.70 | 0.90 | 0.20 | 0.33 | 0.47 | 0.60 |

| 2 1/2 | 0.60 | 0.85 | 1.35 | 1.80 | 0.40 | 0.60 | 0.90 | 1.20 |

| 3 | 0.90 | 1.30 | 2.00 | 2.90 | 0.60 | 0.90 | 1.35 | 1.90 |

| 4 | 1.40 | 2.00 | 4.00 | 5.90 | 0.90 | 1.35 | 2.65 | 3.90 |

| 5 | 2.90 | 3.60 | 6.50 | 9.70 | 1.95 | 2.40 | 4.35 | 6.50 |

| 6 | 4.00 | 5.00 | 10.5 | 16.0 | 2.70 | 3.35 | 7.00 | 10.5 |

| 8 | 7.40 | 10.0 | 21.5 | 33.5 | 4.90 | 6.70 | 14.5 | 22.5 |

| 10 | 13.6 | 16.8 | 38.5 | 52.5 | 9.10 | 11.2 | 25.6 | 35.0 |

| 12 | 23.4 | 27.0 | 59.0 | 79.0 | 15.6 | 18.0 | 39.5 | 53.0 |

| 14 | 29.0 | 35.0 | 70.0 | 94.0 | 19.3 | 23.5 | 47.0 | 63.0 |

| 16 | 41.3 | 47.0 | 95.0 | 125 | 27.5 | 31.5 | 63.5 | 84.0 |

| 18 | 51.8 | 59.0 | 120 | 158 | 34.5 | 39.5 | 80.0 | 105 |

| 20 | 73.0 | 85.0 | 146 | 194 | 49.0 | 57.0 | 98.0 | 129 |

| 24 | 122 | 140 | 210 | 282 | 82.0 | 94.0 | 140 | 188 |

| Approximate weights in kg, density 8 kg/dm3 | ||||||||

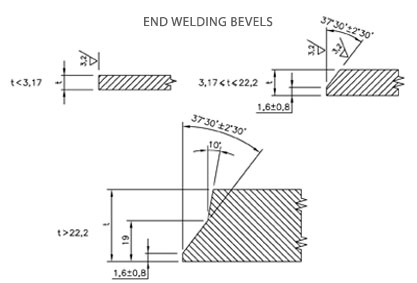

ELBOWS - End welding bevels